VHP Negative Pressure Isolator for Filling Machine

5.0

Warranty:

1 Year

Used:

Cleanroom, Laboratory, Dust-free Room

Type:

Electric

Start Port:

Shanghai

shipping:

EXW Suzhou; CIF;CFR

Packing Details:

Plywood case; pallet

MOQ:

1 pc

Material:

304/316 Stainless Steel

Color:

Silver

Brand name:

SUZHOU PHARMA

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

After Warranty Service: Video technical support, Online support

Certification: CE ISO GMP

Name: VHP Isolator

Application: Cleanroom, lab, dust-free room

Compressed Air Volume: 0.5MPa

Power V/Kw: AC220 /3.5

Transfer Cabin Size (W*D*H)mm: 600*680*700

Operating Cabin Size(W*D*H)mm: 1195*680*700

Outer Dimension(W*D*H)mm: 1600*880*2250

Cabin Material: External Full 304 Stainless Steel

Limit Discounts

Limit Discounts

Description

Technical feature

1.PLC control, color touch screen display, stable and reliable work, intuitive and simple interface;

2.With the function of dehumidification, the humidity in the sterilization space can be adjusted and controlled, and the

environmental requirements for the sterilization space are relatively low;

3.Data saving and printing;

4.Sterilization parameters memory preservation function, sterilization directly out;

5.Low temperature sterilization process at room temperature;

6.Weighing function of hydrogen peroxide solution, warning when solution is insufficient;

7.Desiccant failure alarm function, prompt the user to replace;

8.Less residue, hydrogen peroxide final decomposition products for water vapor and oxygen, no toxic side products;

9.Short sterilization time and low operating cost;

10.Hydrogen peroxide gas material compatibility, plastic, rubber, electronic products have a good compatibility;

11.Broad-spectrum sterilization, the ability to kill thermophilic fat spores is106;

12.Suitable for online sterilization in closed space and freeze-drying machine.

Installation and debugging

The equipment is mainly composed of storage compartment, fan, drying oven, heater, carburetor, peristaltic pump, sensor,

electrical system and control panel. Please pay attention to the following points before debugging:

1.After unpacking, take the equipment out smoothly and place it in a stable room;

2.Clean the outside of the equipment and do not flush with water;

3.Power on the equipment to ensure that the input voltage is in line with the rated voltage of the equipment;

4.After starting up, observe whether the Settings meet the work requirements;

5.Open the system for trial operation, observe whether the parameters curve is normal under the working condition, and whether the

fan, heater, peristaltic pump and carburetor are working normally;

6.Take 35% hydrogen peroxide to the specified amount of solution;

7.Connect the device input line.

It is suitable for cleaning and disinfection of equipment and instruments in clean area.

1.PLC control, color touch screen display, stable and reliable work, intuitive and simple interface;

2.With the function of dehumidification, the humidity in the sterilization space can be adjusted and controlled, and the

environmental requirements for the sterilization space are relatively low;

3.Data saving and printing;

4.Sterilization parameters memory preservation function, sterilization directly out;

5.Low temperature sterilization process at room temperature;

6.Weighing function of hydrogen peroxide solution, warning when solution is insufficient;

7.Desiccant failure alarm function, prompt the user to replace;

8.Less residue, hydrogen peroxide final decomposition products for water vapor and oxygen, no toxic side products;

9.Short sterilization time and low operating cost;

10.Hydrogen peroxide gas material compatibility, plastic, rubber, electronic products have a good compatibility;

11.Broad-spectrum sterilization, the ability to kill thermophilic fat spores is106;

12.Suitable for online sterilization in closed space and freeze-drying machine.

Installation and debugging

The equipment is mainly composed of storage compartment, fan, drying oven, heater, carburetor, peristaltic pump, sensor,

electrical system and control panel. Please pay attention to the following points before debugging:

1.After unpacking, take the equipment out smoothly and place it in a stable room;

2.Clean the outside of the equipment and do not flush with water;

3.Power on the equipment to ensure that the input voltage is in line with the rated voltage of the equipment;

4.After starting up, observe whether the Settings meet the work requirements;

5.Open the system for trial operation, observe whether the parameters curve is normal under the working condition, and whether the

fan, heater, peristaltic pump and carburetor are working normally;

6.Take 35% hydrogen peroxide to the specified amount of solution;

7.Connect the device input line.

It is suitable for cleaning and disinfection of equipment and instruments in clean area.

| PRODUCT INTRODUCTION.Negative pressure isolator is an isolation and protection equipment with high tightness that forms negative pressure during process operation. Generally, it is composed of operation cabin,continuous bagging system, RTP valve system, control system, cleaning system,sterilization system,waste liquid collection module,etc. Users can configure functions according to process requirements, mainly used in the operation process that causes toxicity and pollution to human body or environment,especialy in anti-tumor drugs Active biological products, animal testing and other industries have been widely used. Product Features.The negative pressure isolator can ensure that the harmful and toxic substances in the operation cabin will not leak out of the cabin. .The negative pressure isolator can automatically adjust the negative pressure in the cabin according to the set value, and has the emergency response function.Once the internal pressure loss or leakage of the isolator is detected,it will automaticaly respond and adjust to ensure that the air flow of the isolator enters the isolator from the background room to avoid the diffusion of toxic substances. ·Reasonable and compact structure, high cost performance. ·It can be equipped with disinfection and inactivation treatment system to achieve disinfection effect ·The waste liquid collection module with respiratory function can be configured to prevent toxic substances from escaping and polluting the environment. ·The discharged air is protected by double-layer filtration to improve the safety of the discharged air. |

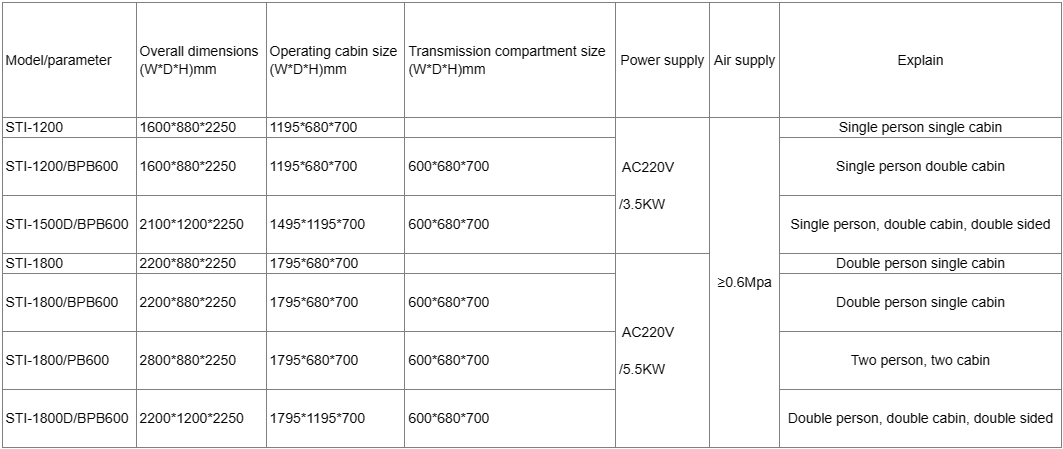

Technical Parameters

| Material | External all 304 stainless steel, internal chamber 316L stainless steel |

| Cleanliness level | Class A |

| Wind speed | 0.45m/s ± 20% |

| Leakage rate | ≤ 0.5% VOL/h (below 100pa) |

| Exhaust volume | ≥ 300m ³/ H |

| Pressure control range | 100pa~+100pa |

| Sterilization efficiency | 6lg |

| VHP residual removal efficiency | ≤ 1PPM |

| Control method | Manual or automatic |

| Noise | ≤ 68dB (A) |

| illumination | ≥ 350LUX |

Installation

Installation

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

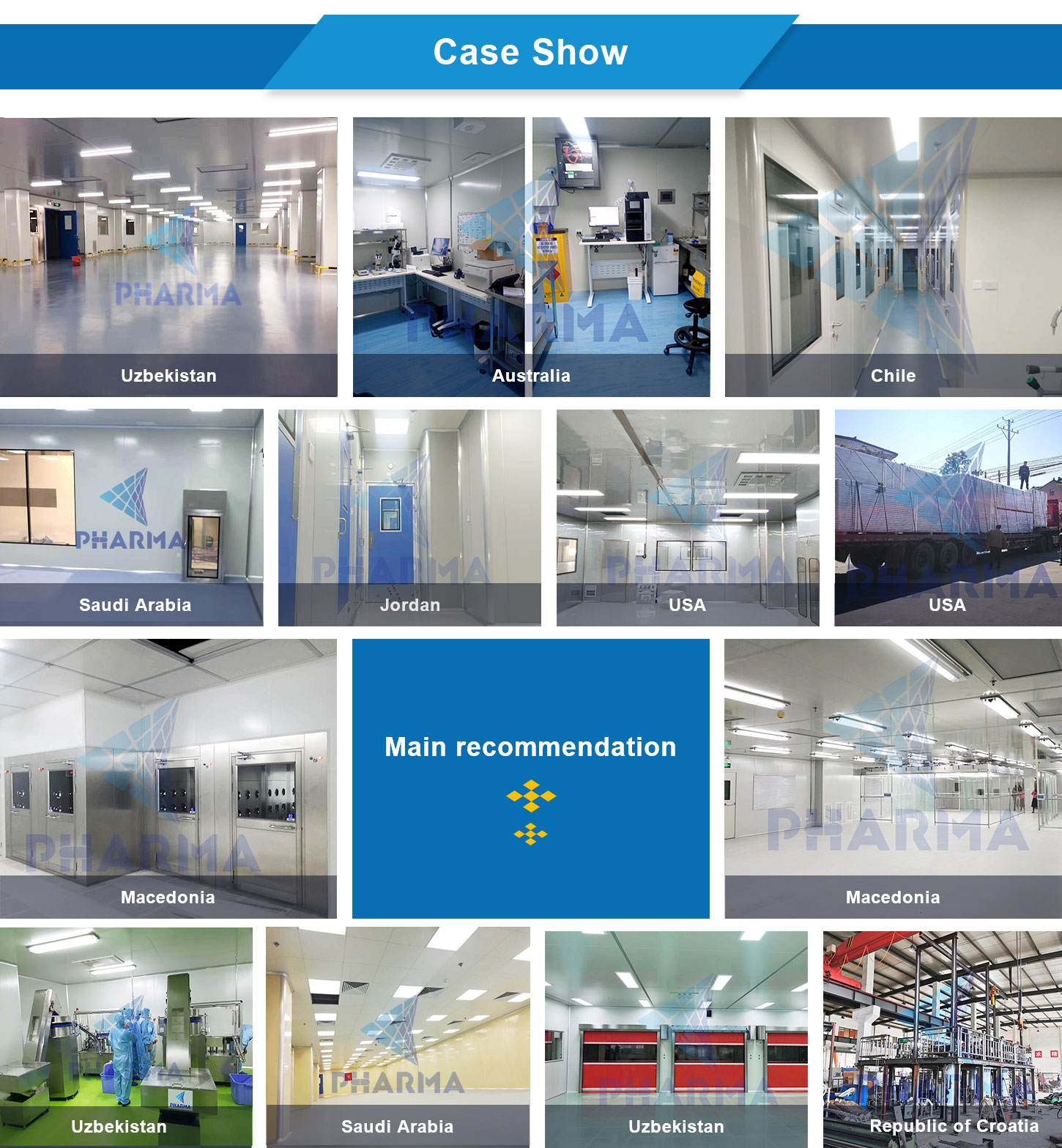

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs! We have more than 16 years of experience in cleanroom turnkey projects , with business all over the world. We adhere to the principle of customer first, serve every cooperative customer attentively, and focus on the standard delivery of each cleanroom project.

Related Products

no data

Contact Us

Telephone: +86-18241958031/

+86-18913598640

Fax: 86-512-65488640

Email: pharma@sz-pharma.com

Whatsapp/Wechat: 008618241958031

Notice:

We hereby declare that our company's only legal contact is through the the above email, Any other similar suffix is a scammer email.

Address: NO.188 xiangwei road, near junction of xiangwei road and chengyang road (the second floor of south building inside of haiji feiyue) Xiangcheng district, Suzhou city, Jiangsu province, China

no data

Copyright © 2025 Suzhou Pharma Machinery Co., Ltd. | Privacy Policy Sitemap